The Difference is Reliability

Precise monitoring maintains stability. Unreliable sensors lead to critical failures.

Stable Monitoring

Unstable Monitoring

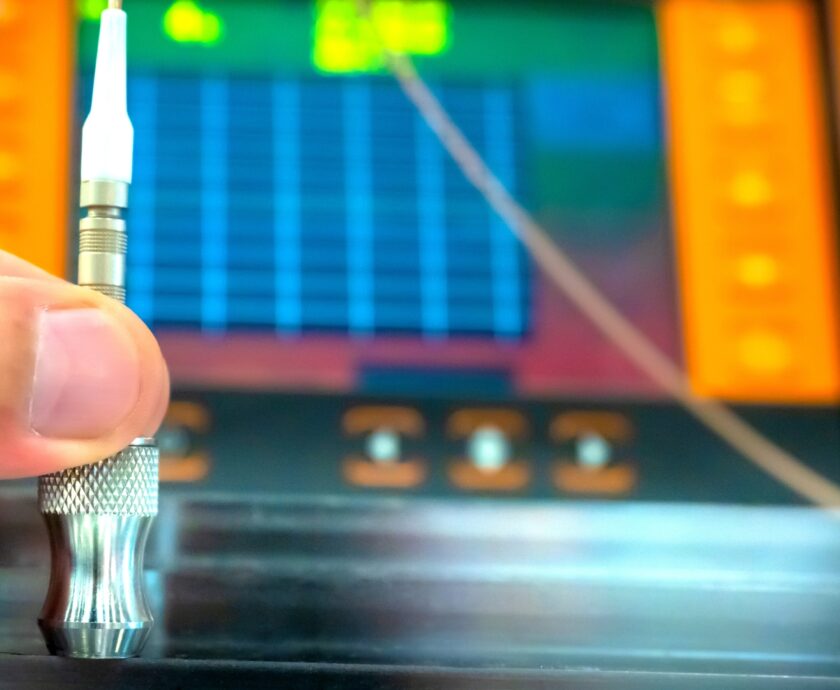

Ever had that feeling, watching a gauge jump around, where you’re not sure if you should trust the process or the instrument? It’s a situation every engineer and operator wants to avoid. The animated gauges on this page tell a story that gets to the heart of this challenge.

Let’s break down what’s happening here.

On one hand, you have the ideal scenario: Stable Monitoring. The needle is steady, predictable, and stays comfortably in the green. This isn’t just a sign of a “good” system; it’s a sign of a reliable one. When you have this level of stability, it’s because you can trust your data. Your temperature sensors are doing their job correctly, giving you an accurate picture of what’s happening inside your process. You have the confidence to make the right decisions, optimize for efficiency, and keep things running smoothly.

But on the other hand, you have a situation we all dread: Unstable Monitoring. The needle is all over the place. Is there a problem with the process, or is the sensor itself failing? This is where uncertainty creeps in, and uncertainty in a critical process is dangerous. An unreliable reading, whether from signal drift, corrosion, or poor calibration, leaves your team guessing. As you can see, that guesswork eventually leads to a critical alert. At that point, a costly, unplanned shutdown isn’t just a possibility; it’s a necessity.

So, what’s the real difference between these two outcomes? It’s not luck; it’s the quality of the instrumentation you choose to rely on.

We’ve all seen the numbers on what an unplanned shutdown can cost; it’s staggering. That’s why viewing your instrumentation as a simple component is a risk. Think of it instead as your first and best line of defence. A high-performance, reliable sensor isn’t just another part; it’s the foundation for control, safety, and operational peace of mind.

Ultimately, the choice is simple. You can react to crises, or you can build a system that prevents them.

Investing in quality instrumentation isn’t just another line item on a budget; it’s one of the best investments you can make in your plant’s long-term reliability and safety. It’s the difference between being in control and just hoping for the best.