If you’re dealing with industrial temperature measurement, you’ve likely come across two main sensors: the Thermocouple and the Resistance Temperature Detector (RTD). They both get the job done, but they work in completely different ways and each has its own set of strengths and weaknesses.

Choosing between them isn’t a matter of which one is universally “better,” but rather, which is the right tool for the specific job at hand. Understanding their core differences is the first step for any engineer or technician aiming to select a sensor that will provide reliable, accurate, and cost-effective service for their application.

The Basics: How Do They Work?

Thermocouples: A thermocouple works on a principle called the Seebeck effect. It is made from two different types of metal wires joined together at one end (the “hot junction”). When this junction is heated, it creates a tiny voltage that is directly proportional to the temperature difference between the hot junction and the other end (the “cold junction”). This voltage is then measured and converted into a temperature reading.

RTDs: An RTD operates on the principle that the electrical resistance of a metal changes predictably with temperature. An RTD consists of a fine wire (most commonly platinum) wrapped around a ceramic or glass core. As the temperature of the metal increases, its resistance to the flow of electricity increases. A precise instrument measures this resistance and converts it into a highly accurate temperature reading.

Head-to-Head Comparison

Let’s compare these two sensors across the five most critical performance criteria.

- Temperature Range

This is often the first and most decisive factor.

- Thermocouples: Have a massive operating range. Depending on the type of metals used (e.g., Type K, J, S, B), they can measure temperatures from cryogenic levels up to 2300°C (4200°F).

- RTDs: Have a more limited range, typically used for temperatures between -200°C and 650°C (-328°F to 1200°F). Above this, the stability of the platinum element can be compromised.

- Winner: Thermocouples, for their sheer breadth of range, especially at the high end.

- Accuracy & Stability

For applications requiring high precision, this is a key differentiator.

- RTDs: High-accuracy RTD temperature sensors are the champions. They provide highly precise, stable, and repeatable readings over long periods with very little drift.

- Thermocouples: Are generally less accurate than RTDs. Their accuracy can be affected by the homogeneity of the wires and they are more prone to drifting over time, especially at high temperatures.

- Winner: RTDs, for applications where precision and long-term stability are paramount.

- Durability & Vibration Resistance

Industrial environments can be rough, and mechanical stress is a major concern.

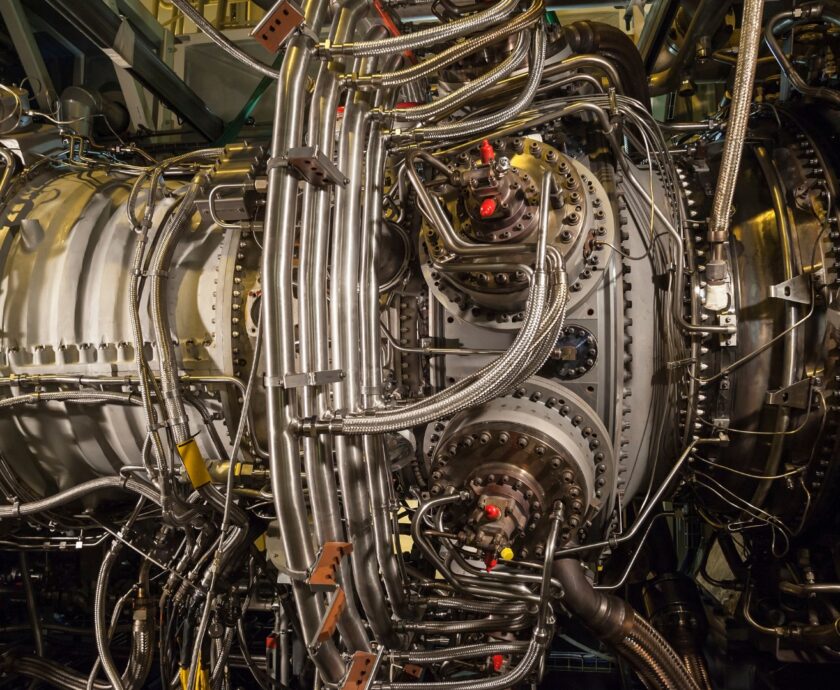

- Thermocouples: Have a simple, robust construction consisting of two welded wires. This makes them very durable and highly resistant to mechanical shock and vibration.

- RTDs: The sensing element is a fine, coiled wire, which makes them more susceptible to damage from severe shock or vibration.

- Winner: Thermocouples, for their ruggedness in demanding mechanical environments.

- Response Time

How quickly a sensor can react to a change in temperature can be critical for process control.

- Thermocouples: Generally have a faster response time. Their sensing junction is smaller and has less mass, allowing them to react more quickly to temperature changes.

- RTDs: Have more mass in their sensing element, which typically results in a slower response time.

- Winner: Thermocouples, when rapid detection of temperature changes is essential.

- Cost

Budget is always a consideration.

- Thermocouples: Are typically less expensive than RTDs. The materials are more common and the construction is simpler.

- RTDs: The use of high-purity platinum and a more complex manufacturing process makes them the more expensive option.

- Winner: Thermocouples, for being the more budget-friendly choice.

Quick Reference Chart

Feature | Thermocouple | RTD (Platinum) | Best For… |

Temp. Range | Very Wide (-200°C to 2300°C) | Moderate (-200°C to 650°C) | Thermocouple: Extreme heat. |

Accuracy | Good | Excellent | RTD: High-precision control. |

Stability | Fair (can drift) | Excellent (very stable) | RTD: Long-term reliability. |

Durability | Excellent (very rugged) | Good (sensitive to vibration) | Thermocouple: High-vibration areas. |

Response Time | Fast | Slower | Thermocouple: Rapid process changes. |

Cost | Lower | Higher | Thermocouple: General purpose & budget-conscious. |

The Right Sensor for the Job

The choice between a thermocouple and an RTD is a classic engineering trade-off. If your application involves extreme temperatures, high vibration, a need for fast response, or a tight budget, a thermocouple is likely the right tool for the job.

If, however, your application operates in a moderate temperature range but demands high accuracy, repeatability, and long-term stability for precise process control, then the superior performance of an RTD is the clear and necessary choice.