Thermowells are built to withstand high pressure, heat, and turbulence. But they have a critical vulnerability: vortex-induced vibration (VIV), which can lead to unexpected equipment failure.

At Thermo Electric Instrumentation, we’ve made it our mission to engineer smarter, safer solutions for temperature measurement. That’s why we developed the helical-strake thermowell, a breakthrough design that addresses VIV at its source. In this article, we explain what vortex-induced vibration is, how it affects your process equipment, and how our Helical strake design helps eliminate it.

What Is Vortex-Induced Vibration?

Vortex-induced vibration happens when fluid flows around a cylinder, such as a thermowell. As it flows, the fluid creates swirling patterns (vortices) that alternate from side to side, pushing the cylinder back and forth.

If these pushes happen at the same rate as the natural vibration frequency of the thermowell, it causes resonance. This greatly increases the vibration and can lead to damage like cracks, sensor failure, or even breakage of the thermowell.

VIV isn’t just a theoretical concern; it’s a practical reliability threat. In high-velocity flows such as steam lines, gas transfer systems, or cryogenic services, thermowells are constantly exposed to vortex shedding forces. Over time, this can lead to:

- Fatigue failure at weld points or flanges

- Sensor drift, leading to inaccurate readings

- Shortened service life, increasing downtime and maintenance costs

Flow velocity restrictions, enforced by conservative design safety margins

Traditional design codes like ASME PTC 19.3 TW-2016 offer guidance on VIV mitigation. However, when process conditions exceed the code’s parameters, such as high flow velocities or restricted insertion lengths, conventional thermowells often fail to comply.

The Thermo Electric Solution: Helical-Strake Thermowells

Rather than reinforce the thermowell with thicker walls or shorten the insertion depth (both of which come with trade-offs) we took a different approach.

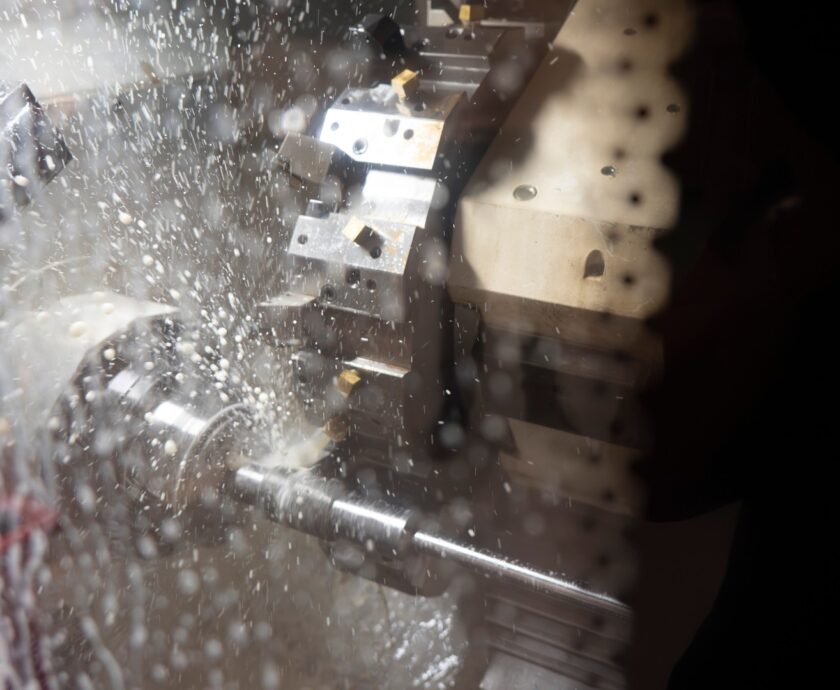

Our engineers developed the helical-strake thermowell, featuring a continuous spiral ridge machined directly into the thermowell stem. Inspired by aerospace and offshore engineering, this strake disrupts the fluid flow around the thermowell, breaking up the regular vortex street before it can form.

This disruption causes vortices to form earlier and less coherently, spreading out energy and reducing lateral forces. The result: no lock-in, no resonance, and significantly reduced vibration.

How the Design Works

The innovation lies in its simplicity. A shallow spiral ridge called a strake is precision-machined into the upper portion of the thermowell. This profile disturbs the shear layers that would normally roll off to form alternating vortices.

Instead of a strong, repeating pattern of vortices (which leads to resonance), the flow becomes more chaotic and fragmented. The fluid forces acting on the thermowell decrease dramatically by as much as 90%, based on both experimental and simulation data.

Because the strake is an integral part of the body, there are no welds or joints that compromise mechanical strength. The result is a robust, vibration-resistant thermowell suitable for extreme process environments.

Validated by Science and Simulation

At Thermo Electric, every product we design is backed by rigorous testing and validation. For our helical-strake thermowell, we carried out a two-pronged study:

- Laboratory Testing

Conducted at TNO’s DN100 air flow loop, our thermowells were equipped with miniature accelerometers and flange-mounted strain gauges. The data revealed that the helical-strake design prevented the formation of strong resonant peaks across a wide velocity range. - Computational Fluid Dynamics (CFD) and Finite Element Analysis (FEA)

Partnering with FEMTO Engineering, we modelled real-world process scenarios, including extreme gas flows of 93 m/s. The simulations confirmed that vibration amplitudes dropped from hundreds of microns in a standard tapered thermowell to just a few tens in the helical version.

Compliance and Code Considerations

Although ASME PTC 19.3 TW-2016 does not yet include provisions for helical strakes, it allows alternative validation methods. When testing or simulation clearly demonstrates that vibration is mitigated, dynamic stress calculations may be omitted. This flexibility enables engineers to use strake-equipped thermowells with confidence, even in applications that would normally exceed standard limits.

When Would We Recommend a Helical-Strake Design?

Our helical-strake design is ideal for:

- High-velocity gas or steam lines

- Services with limited insertion depth or retrofitted piping

- Critical measurement points where failure would have high operational impact

- Applications exceeding conventional ASME VIV thresholds

The design offers a drop-in solution using standard flanges. The outer diameter increase is minimal, and there’s no impact on sensor fit or responsiveness.

The Benefits at a Glance

| Challenge | Helical-Strake Solution |

| Vibration from vortex shedding | Disrupts vortex street formation |

| Resonant stress | Prevents lock-in to natural frequency |

| Fatigue and early failure | Reduces vibration amplitude up to 90% |

| Design limitations | Enables higher velocities and longer lengths |

| Compliance issues | CFD-backed validation supports safe design |

Innovation in the Flow

Vortex-induced vibration might be invisible to the eye, but its impact on thermowell performance is anything but minor, especially in today’s demanding process environments. At Thermo Electric Instrumentation, we’ve tackled this challenge not by compromising on size or strength, but by rethinking the way thermowells behave in flowing fluids.

Our helical-strake thermowell is another option when standard thermowells won’t perform. Backed by rigorous testing and real-world results, this type of design delivers the reliability and accuracy engineers, operators, and plant operators depend on.

Get in touch to discover exactly how we make precision temperature measurement possible, even in the harshest conditions.