Thermocouple drift is one of the most persistent challenges in temperature measurement. Technically, drift refers to the gradual change in output voltage (Electromotive Force or EMF) over time, even when the actual temperature remains constant. It is the slow movement of the measured value away from the true value, an error that worsens with time and harsh service conditions.

In contrast, stability reflects the ability of a system to maintain accurate readings over extended periods without recalibration.

Inaccurate temperature measurement carries a significant cost:

- Process inefficiency and energy waste.

- Reduced product quality in temperature-sensitive processes.

- Safety risks in chemical or high-pressure operations.

- Higher maintenance costs due to unscheduled sensor failures.

Even a deviation of +/- 5°C can lead to off-spec catalysts, inefficient combustion, or material defects, making drift prevention a critical part of reliable process control.

What Causes Thermocouple Drift?

1. Inherent Material Degradation

Unlike RTDs, which offer excellent long-term stability, thermocouples begin to degrade from the moment they are exposed to high temperatures. The Seebeck voltage, the EMF that defines a thermocouple’s reading, changes as the metals age or lose homogeneity.

2. The Type K Challenge (Chromel–Alumel)

For Type K thermocouples, drift behavior is well documented but notoriously difficult to manage at elevated temperatures. The primary cause of drift in Type K sensors is chemical and metallurgical changes within the alloy, specifically the loss of chromium from the positive leg at high temperatures.

This depletion alters the thermoelectric output, resulting in increasing measurement error over time. Unfortunately, this phenomenon is unpredictable:

- There is no universal data available on exactly how much drift will occur or after what time it starts.

- Drift becomes significantly more pronounced with high heat, contamination, and repeated thermal cycling.

3. Metallurgical and Chemical Effects

Beyond the general loss of chromium, specific environmental reactions accelerate drift:

- Oxidation and Green Rot: Type K thermocouples (Ni-Cr/Ni-Al) are susceptible to “green rot”, severe chromium depletion in low-oxygen atmospheres. This causes large negative drifts, particularly between 815°C and 1040°C.

- Grain Growth and Rhodium Diffusion: In Type R and S thermocouples, prolonged exposure above 1300°C can cause diffusion between platinum and rhodium legs, leading to calibration loss and brittleness.

- Contamination: At high temperatures, reactions between metals, insulation (MgO or Al2O3), and process gases can “poison” the junction, permanently altering its EMF output.

4. Mechanical and Environmental Stress

Mechanical vibration and thermal cycling lead to:

- Microcracks in the sheath or wires.

- Changes in crystalline structure.

- Noise and intermittent signal loss.

- Accelerated wear of thermowells or connectors.

Moisture is another silent killer: Magnesium oxide (MgO) insulation is highly hygroscopic. If not properly sealed, it absorbs moisture, causing leakage currents and signal drift.

5. EMF Inhomogeneity

As a thermocouple operates, the composition of its metals may vary along its length due to temperature gradients. This creates inhomogeneity, making post-use recalibration unreliable; the EMF measured in a lab may no longer represent the field conditions under which the sensor operates.

How to Identify and Monitor Drift

Because drift, particularly in Type K sensors, is unpredictable, periodic calibration and smart monitoring are essential.

1. Smart Diagnostics

Modern intelligent transmitters detect early signs of thermocouple failure:

- Sensor Drift Alerts: Compare dual-element signals to identify divergence.

- Loop Resistance Monitoring: Detects wire thinning or corrosion.

- Noise Analysis: Highlights loose connections or insulation breakdowns.

2. Dual Thermocouple Assemblies

A dual-element configuration allows engineers to compare outputs in real time. If the primary sensor begins to drift or fails, the system triggers a switch to the backup element (“hot backup”), minimizing downtime.

3. Calibration and Verification

Routine recalibration is the only way to combat the unpredictable nature of drift. Our calibration facilities perform traceable testing up to 1500°C (RvA/ILAC accredited). Utilizing fixed-point or comparison methods (as described in IEC 60584) verifies that sensors remain within tolerance.

Engineering Solutions

1. Select the Right Thermocouple Type

- Type N (Nicrosil–Nisil): Offers superior high-temperature stability and oxidation resistance compared to Type K. Ideal up to 1200°C.

- Types R, S, B: Noble-metal thermocouples (platinum-rhodium) for extreme temperatures (up to 1700°C), offering minimal drift and reduced grain growth.

2. Use Protective Sheaths and Thermowells

Thermowells and protection tubes shield sensors from corrosion, mechanical damage, and flow-induced vibration. Materials should be selected based on the environment:

- SS 316: For general industrial use.

- Inconel 600 or Hastelloy: For high-temperature oxidation resistance.

- Ceramic or Titanium: For corrosive gases.

We adhere to the ASME PTC 19.3 TW-2016 design principles to ensure optimal stress, frequency, and vibration safety factors.

3. Vibration Mitigation

- Helical strake thermowells can reduce vortex-induced vibration (VIV) by up to 90%.

- Non-intrusive sensors eliminate vibration failure risk altogether.

4. Intelligent Transmitters

Microprocessor-based transmitters maintain accuracy by self-referencing internal standards, providing continuous diagnostics and compensation for drift.

Operational Best Practices

1. Calibration and Scheduling

Because Type K drift is unpredictable and data on onset times are unavailable, periodic calibration is mandatory. Thermo Electric recommends traceability to NIST or equivalent standards using:

- Comparison Method: Against a certified reference thermocouple.

- Fixed-Point Method: Using phase-change temperatures of pure metals.

2. Environmental Control

- Cold Junction Compensation (CJC): Ensure accurate reference temperature using transmitters with built-in electronic compensation.

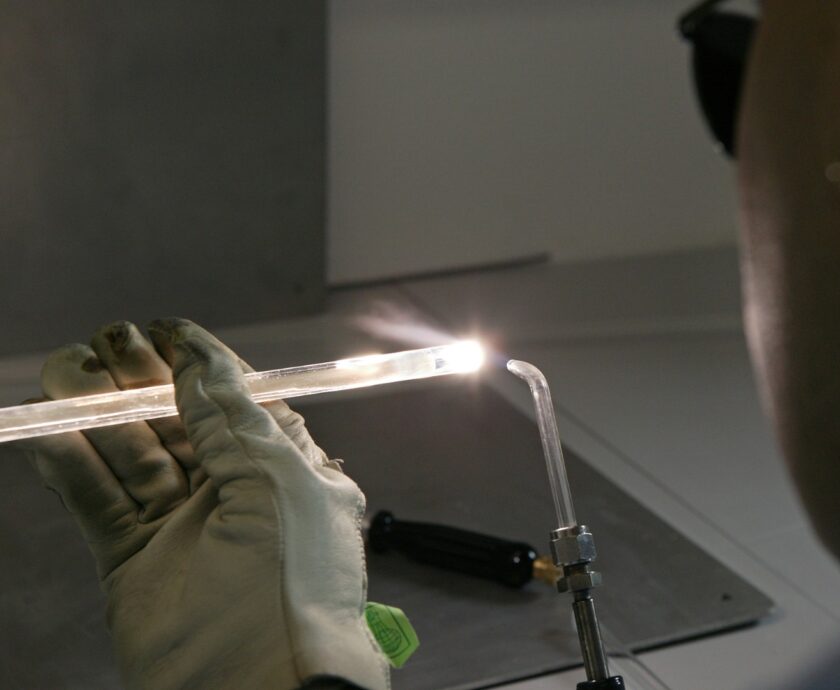

- Moisture Protection: Always seal MI cable ends immediately after heating and drying to avoid MgO contamination.

- Oxygen Management: For Type K thermocouples, ensure sufficient oxygen flow or use getters to prevent green rot.

3. Installation and Wiring

- Use extension wires matching thermocouple alloys to avoid false junctions.

- Keep signal leads short, twisted, and shielded to reduce noise.

- Observe polarity; reversed leads can create errors twice the ambient difference.

Wrapping Up

Thermocouple drift is inevitable, but its impact is controllable. By understanding the chemical limitations of alloys like Type K, protecting them with engineered thermowells, and leveraging smart transmitters with built-in diagnostics, engineers can dramatically extend sensor life.

Accurate measurement isn’t just about precision; it’s about trust. When your temperature readings stay stable, your process stays efficient, safe, and cost-effective.