An RTD sensor might be incredibly precise, but that precision doesn’t mean much if the signal gets distorted before it reaches your control system.

The real weak point isn’t usually the sensor itself, it’s the parts we often overlook: the wires and connectors.

Let’s break down why they’re so important:

Wire Configuration

- 2-Wire: This is the simplest setup, but it comes with a big drawback, the resistance of the wires adds to the sensor’s reading. That can throw off accuracy, especially over longer runs.

- 3-Wire: A solid step up. This arrangement lets the system estimate and correct for lead wire resistance, which gives you a more accurate result.

- 4-Wire: The best choice when precision matters most. It completely eliminates lead wire resistance from the measurement, making it ideal for lab environments and critical processes.

Connector Quality

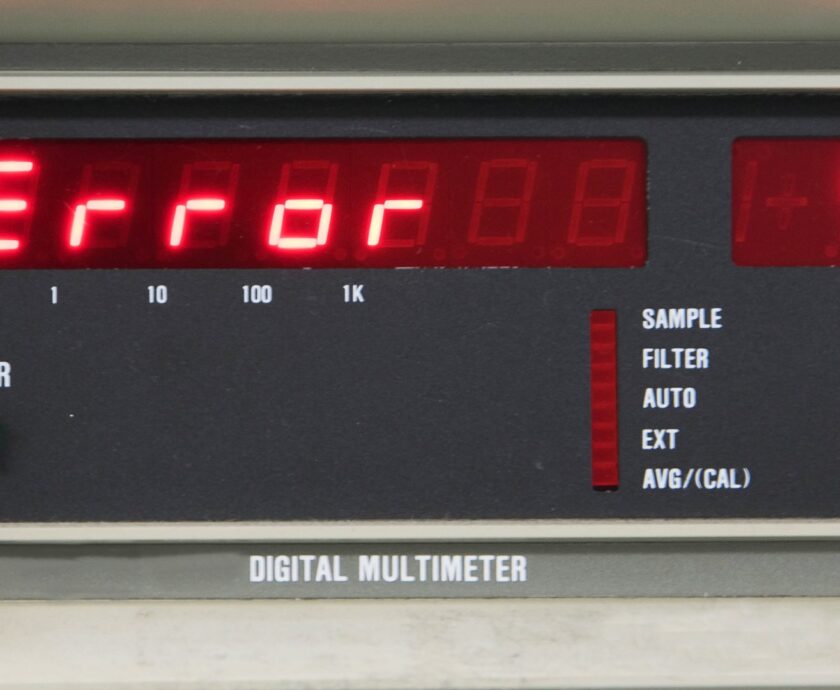

Connectors are often the most overlooked yet the most failure-prone part of the setup. Loose or poorly sealed connections can be shaken loose by vibration, causing signal dropouts.

Moisture can get in and corrode contacts, changing resistance and messing with your readings. A rugged, properly sealed connector isn’t just a nice-to-have, it’s essential.

The Takeaway

When choosing Industrial resistance temperature sensors, don’t stop at the sensor itself. The wire configuration and connector quality play a huge role in the overall accuracy and reliability of your system. A precise sensor is only as good as the components that carry its signal.