In the semiconductor industry, “margin for error” is a virtually non-existent concept. Whether in diffusion furnaces, etching processes, or deposition layers, a temperature deviation of a fraction of a degree can compromise yield and ruin costly batches of wafers.

Recently, a major semiconductor manufacturer faced a dual challenge. They needed a supplier capable of delivering ultra-precise, clean-room-certified temperature profiles, but they also needed the agility and communication speed of a local partner. They turned to Thermo Electric Instrumentation.

This collaboration highlights a critical shift in the industry: the need for suppliers who can combine global regulatory compliance with local, responsive support.

The Technical Challenge: Purity at 1500°C

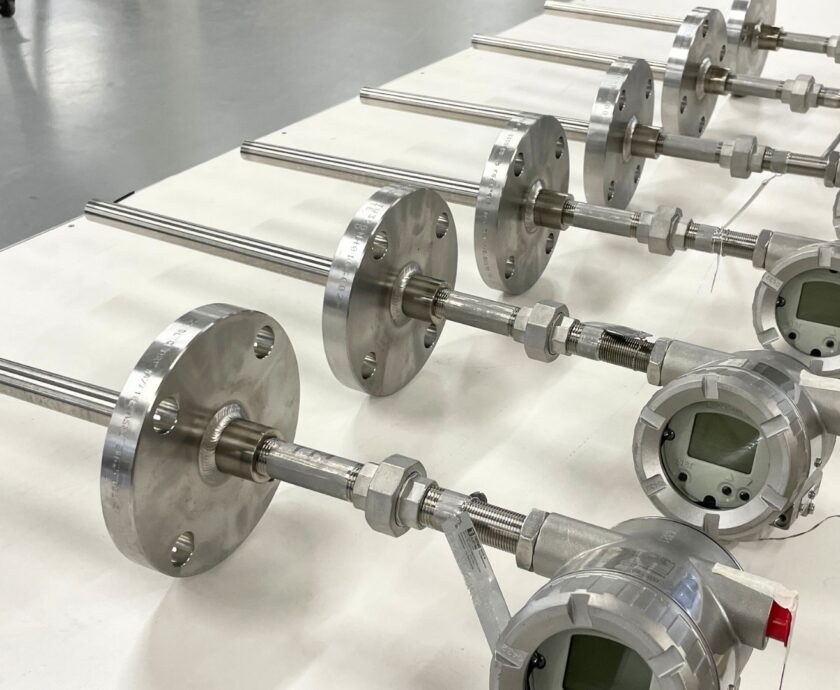

The core requirement for this project was the delivery of specialized Spike and Profile Thermocouples for diffusion furnace processes. These are not off-the-shelf components. They operate in environments where extreme heat meets corrosive gases, and where the slightest particulate contamination can be catastrophic.

Our solution was rooted in our deep integration with the specific needs of the semiconductor sector:

- Clean Room Chain of Custody: To mitigate contamination risks, manufacturing took place entirely within our certified clean room environment.

- Validated Calibration: Using our in-house ISO 17025–accredited laboratory, we performed rigorous calibration and validation up to 1500°C, ensuring that the sensors provide drift-free data even at the extremes of the thermal envelope.

- Industry Pre-Qualification: Because we hold various manufacturer approvals, the customer could bypass lengthy vetting stages, confident in our adherence to OEM specifications.

“In semiconductor fabrication, a sensor isn’t just a measurement device; it is the gatekeeper of process integrity.”

The Strategic Advantage: The Power of “Local”

While technical specs are non-negotiable, supply chain logistics often determine the success of a partnership. Many European manufacturers struggle with the time-zone delays and logistical hurdles of relying on U.S.-based suppliers.

For this customer, our headquarters in Waddinxveen, The Netherlands, proved to be a decisive advantage.

- Real-Time Collaboration: Direct access to engineering teams without waiting for the US wake-up cycle allowed for rapid prototyping and technical problem solving.

- LEAN Agility: Our LEAN-certified office and production environment meant we could adapt to schedule changes and execute orders faster than larger, more distant competitors.

Wrapping Up

This project reaffirms a core belief at Thermo Electric: High-tech manufacturing requires more than just hardware; it requires a partnership structure that supports the customer’s timeline.

By delivering ISO-certified, clean-room manufactured solutions from a centralized European hub, we provided this major manufacturer with the two things they value most: Regulatory Confidence and Operational Speed.