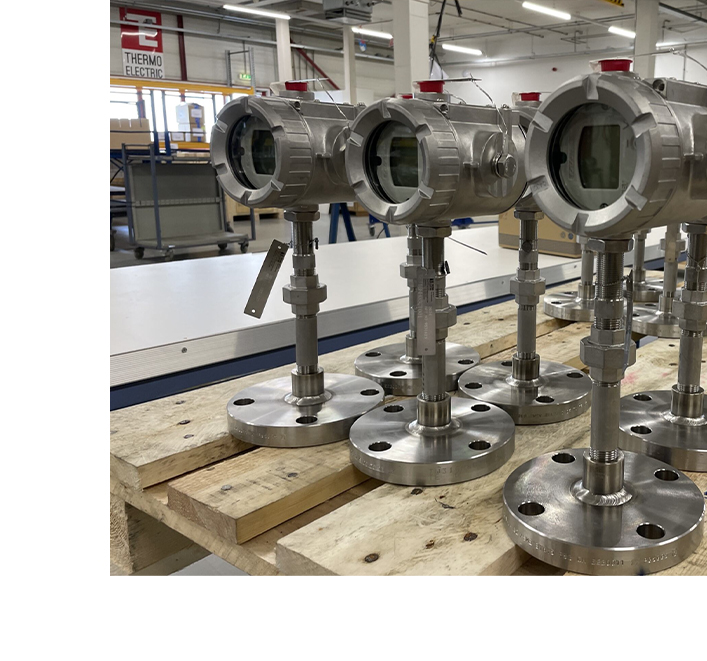

For the world’s most demanding sectors.

Process monitoring in refineries and gas fields

Our resistance temperature detectors (RTDs) deliver stable and accurate temperature sensing in refineries, pipelines, and offshore platforms. Each resistance temperature detector sensor is built to endure vibration, pressure, and corrosive hydrocarbons, ensuring safe and efficient process monitoring in demanding oil and gas environments.

Accurate reaction control

Thermo Electric resistance temperature sensors provide precise, repeatable data for process reactors, distillation units, and heat exchangers. Each resistance temperature device is engineered for chemical compatibility, long-term stability, and reliable operation under fluctuating process conditions.

Wafer temperature control to ± 0.1 °C at 450 °C

Ultra-high-accuracy resistance temperature detectors ensure precise wafer and chamber control during semiconductor and solar cell fabrication. These thin-film resistance thermometer detectors maintain sub-degree accuracy with excellent linearity and minimal drift in high-purity, high-temperature environments.

Engine and turbine temperature control

Lightweight, high-stability resistance temperature detectors (RTDs) deliver accurate thermal feedback for turbines, engines, and aerospace test facilities. Each resistance temperature detector sensor is designed for rapid response and endurance in high-vibration, high-pressure conditions.

Generator and turbine temperature sensing

Our resistance temperature detector sensors ensure reliable monitoring of generator windings, turbines, and bearings in conventional and renewable power plants. Engineered for long-term stability, these resistance thermometer detectors support predictive maintenance and operational efficiency.

Calibration and experimental measurements

High-precision resistance temperature detectors (RTDs) deliver traceable accuracy for calibration baths, material testing, and environmental chambers. Each resistance temperature device provides excellent repeatability and conformity to IEC 60751 standards, ideal for metrology and advanced research applications.

4-Wire RTDs

The 4-wire configuration represents the highest standard for accuracy in RTD measurement across critical industrial applications.

3-Wire RTDs

The 3-wire configuration is widely used in industrial applications and offers a good level of lead resistance compensation compared to 2-wire setup.

Dual Element RTDs

A dual element RTD is a single sensor assembly that contains two independent sensing elements housed within one sensor sheath.

Thin-Film RTDs

Thin-film sensors are characterized by their method of construction, where the resistive material is deposited onto a substrate.

Class B RTDs

Class B sensors define the minimal acceptable accuracy tolerance for conformance to the IEC 60751 standard over a range of temperatures.

Spring-Loaded Sensors

A spring loaded RTD style provides continuous contact between the sensor and the bottom of a thermowell.

Class A RTDs

RTDs are classified according to the tolerance. Class A defines a higher accuracy requirement based on the IEC 751 standard.

Wire-Wound RTDs

Wire-wound RTDs, particularly those using a coiled or helical design, are often contrasted with thin-film types in terms of performance and stability.

How We Stack Up

Engineering Excellence

As a leading temperature sensing solutions provider, we focus on integrating sustainability principles throughout our operations. We strive to align our business practices with international standards, delivering high-quality, innovative products while maintaining a strong commitment to sustainability.

Quality & Accreditation

We emphasise environmental management, social responsibility, and quality assurance. By adhering to ISO 14001 and ISO45001, we showcase our commitment to the environment. We also promote employee well-being, diversity, and community engagement and maintain certifications in international standards, such as ISO 9001.

Operational Reliability

Our approach encompasses security, alignment with Sustainable Development Goals (SDGs), and robust governance and accountability. We prioritise protecting assets and information systems, actively contribute to the UN's SDGs, and ensure transparency and ethical conduct.

Learn About Resistance Temperature Sensors for Industrial Applications

What Is a Resistance Temperature Detector?

How Resistance Temperature Detector Sensors Work

RTD Design & Construction

RTD Wiring Configurations

Common RTD Types

Accuracy Classes

In modern industrial processes, from petrochemical and chemical manufacturing to semiconductor production, precision in temperature measurement is essential.

A Resistance Temperature Detector (RTD), also known as a resistance temperature sensor or resistance temperature device, delivers exceptional accuracy and long-term stability across demanding environments.

An RTD operates by converting temperature changes into electrical resistance. As the metal element (usually platinum) heats or cools, its resistance changes in a predictable way, providing a precise temperature reading.

While “RTD” refers to the sensing element, the term Platinum Resistance Thermometer (PRT) is often used to describe the full probe assembly.

The working principle of a resistance temperature detector sensor relies on a fundamental property of metals: resistance increases as temperature rises. This is known as a Positive Temperature Coefficient (PTC) effect.

When a controlled current passes through the RTD element, the resulting voltage drop is measured to determine temperature.

Because the relationship between temperature and resistance is well-defined.

These resistance temperature detector sensors are therefore valued for their repeatability, reliability, and calibration stability, making them a preferred choice across critical industrial systems.

Design & Construction

- Minimising Self-Heating: Measuring currents are kept below 1 mA to prevent internal heating errors.

- Sensing Materials: Platinum is the industry standard due to its stability and linear resistance-temperature relationship.

- Element Types:

- Wire-Wound Elements: Platinum wire fused into ceramic or glass, offers maximum precision, less vibration tolerance.

- Thin-Film Elements: Platinum film deposited on a ceramic substrate, fast response, excellent shock resistance.

Configuration | Description | Accuracy |

2-Wire | Simplest setup | Least accurate; no lead resistance compensation |

3-Wire | Industrial standard | Compensates for equal lead resistances |

4-Wire | Laboratory-grade precision | Fully eliminates lead resistance errors |

For installations over long distances, accuracy can be preserved using a 4–20 mA transmitter located near the RTD sensor.

RTDs conform to IEC 60751:2008 (Industrial Platinum Resistance Thermometers and Sensors).

Type | Nominal Resistance | Temperature Range | Notes |

Pt100 | 100 Ω @ 0 °C | –200 °C to 650 °C | Global standard |

Pt500 | 500 Ω @ 0 °C | –200 °C to 600 °C | Higher sensitivity |

Pt1000 | 1000 Ω @ 0 °C | –200 °C to 600 °C | Highest signal-to-noise ratio |

The IEC 60751 standard defines the ideal resistance curve, a common alpha value of 0.00385 Ω/Ω/°C, and the following accuracy classes (IEC 60751):

- Class A: ± (0.15 + 0.002 × |t|) °C

- Class B: ± (0.3 + 0.005 × |t|) °C

- 1/10 DIN: ± 0.15 °C typical between 0 °C and 100 °C

A high‑quality transmitter typically adds only ±0.1 °C, so sensor tolerance dominates the system error unless further trimmed with sensor matching.

Click to go to our ITS-90 RTD Calculator | RTD R ↔ T Solver a quick-reference utility for engineers and technicians working with Resistance Temperature Detectors (RTDs).

Reliable Temperature Measurement

We understand the critical role that reliable temperature measurement plays in your industrial processes. Our robust line of industrial temperature sensing solutions are meticulously engineered to deliver high quality, reliable temperature measurement, ensuring the smooth and efficient operation of your industrial applications.

How can I improve accuracy in long cable runs with RTD sensors?

Long cable runs introduce lead wire resistance, which can distort readings. Choosing a 3-wire or 4-wire resistance temperature detector compensates for this effect by allowing the measurement circuit to cancel out cable resistance. Shielded, twisted-pair cables and proper grounding also reduce noise and improve accuracy in industrial installations.

What causes intermittent signal loss in resistance temperature devices?

Intermittent signals from a resistance temperature device are often due to loose terminal connections, moisture ingress, or vibration at the probe head. Ensure terminals are properly clamped, use sealed connection heads with IP-rated protection, and select spring-loaded RTDs to maintain stable contact inside thermowells.

Can resistance temperature detectors be repaired or recalibrated instead of replaced?

In many cases, a resistance temperature detector (RTD) can be recalibrated if the sensing element is still intact. However, if insulation resistance has deteriorated or the probe has been mechanically damaged, replacement is the safer option. Thermo Electric offers recalibration and sensor matching services to restore certified accuracy.

How do I prevent sensor failure in high-vibration or high-pressure systems?

For turbines, compressors, and reactors, specify resistance temperature detector sensors with vibration-resistant construction and welded metal sheaths. Using mineral-insulated leads, compression fittings, and strain-relief cable glands will prevent mechanical fatigue and electrical failure under dynamic loads.

How can I customize a resistance temperature detector for my process?

Thermo Electric designs custom resistance temperature detectors for unique requirements such as miniature probes, extended temperature ranges, or hazardous area approvals. Engineers can specify sheath material, diameter, insertion length, wiring configuration, and accuracy class to match any industrial, laboratory, or R&D environment.

Are resistance temperature detectors compatible with my existing control or DCS system?

Yes. Most resistance temperature detectors (RTDs) and resistance temperature sensors output a standard resistance signal (typically 100 Ω at 0 °C for Pt100 elements), which can be easily integrated with PLCs, transmitters, and distributed control systems. For long-distance signal transmission or analog input cards, a 4–20 mA transmitter can be added directly to the RTD head or junction box for plug-and-play compatibility.

DO YOU HAVE A PROJECT IN MIND?

REQUEST Brochure

Complete this form below and we will automatically send you our latest brochure.