It’s a common scenario in industrial settings: a process starts behaving erratically, a critical temperature reading goes haywire, or perhaps there’s no reading at all. The first suspect? The temperature sensor. Often, it gets blamed for faults that are actually caused by other factors or, more frequently, by environmental stresses that aren’t immediately obvious.

While modern temperature sensors are remarkably robust, they are not invincible. Understanding why they fail is critical for accurate troubleshooting, preventing future downtime, and ultimately saving costs. This guide breaks down the five most common culprits behind temperature sensor failures, helping you pinpoint the real problem.

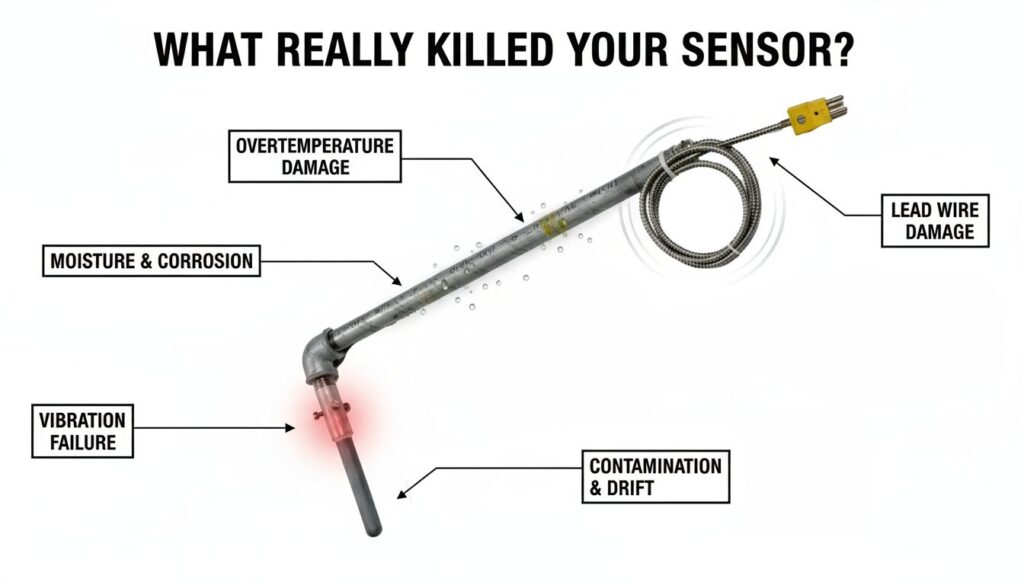

The 5 Common Culprits Behind Sensor Failure

1. Mechanical Stress (Vibration & Shock)

The industrial world is often a world of movement. Pumps hum, machinery vibrates, and even minor bumps can send shockwaves through your equipment. Both RTDs and thermocouples can fall victim to these forces.

- RTDs: These sensors rely on a very fine wire (often platinum) coiled and supported within a sheath. Constant vibration can cause the delicate wire to fracture, leading to an open circuit (no reading) or intermittent contact (erratic readings). Sudden impacts can also shatter the ceramic, rendering the RTD useless.

- Thermocouples: While generally more robust due to their simpler construction, the welded junction of a thermocouple can eventually fail under continuous mechanical stress. The insulation protecting the internal wires can also degrade, leading to short circuits or signal interference.

Diagnosis Tip: If readings are intermittent or suddenly disappear after a period of intense vibration or a known impact, mechanical stress is a strong candidate.

2. Moisture & Corrosion

Water, chemicals, and humidity are silent killers for many electronic components, and temperature sensors are no exception. Even small amounts of ingress can lead to significant problems.

- How it happens: If the sensor’s protective sheath or head isn’t properly sealed, or if the process environment degrades the seal over time, moisture can enter. This is especially true for terminal heads where lead wires connect.

- The Damage: Once inside, moisture can cause:

- Corrosion: Directly attacking the sensor’s internal wiring, lead wires, or terminal connections, increasing resistance, creating short circuits, or causing open circuits.

- Electrical Leakage: Moisture can create conductive paths, especially with RTDs, leading to false resistance readings and inaccurate temperature measurements.

- Diagnosis Tip: Look for visible signs of rust, discoloration, or liquid inside the terminal head. Erratic or drifting readings, particularly in humid environments or after washdowns, can also point to moisture ingress.

3. Lead Wire Damage

It’s a common misconception that sensor failures always occur at the tip where the temperature is being measured. In reality, the most frequent point of failure is often the wiring connecting the sensor to the control system.

- Common Causes:

- Abrasion: Wires rubbing against sharp edges, machinery, or moving parts.

- Crimping/Bending: Wires being pinched, excessively bent, or accidentally cut during installation or maintenance.

- Heat Damage: Exposure to temperatures exceeding the cable’s insulation rating, causing the insulation to melt or become brittle, leading to short circuits or open circuits.

- Chemical Attack: Exposure to corrosive chemicals that degrade the cable’s outer jacket and internal insulation.

- The Impact: Damaged lead wires can result in open circuits (no reading), short circuits (false readings, often low), or intermittent connections (erratic readings).

- Diagnosis Tip: Visually inspect the entire length of the lead wire from the sensor to the transmitter/controller. Pay close attention to pinch points, areas of movement, and high-heat zones.

4. Exceeding Temperature Limits (Overtemperature)

Every sensor has a specified maximum operating temperature. Pushing a sensor beyond this limit, even for a short period, can cause irreversible damage and significantly impact its accuracy.

- RTDs: High temperatures can cause the platinum wire element to anneal (change its crystalline structure), leading to permanent upward shifts in resistance and inaccurate readings. In extreme cases, the wire can melt.

- Thermocouples: Over-temperature exposure can cause the thermoelectric materials to degrade, change their composition, or the weld junction to melt, leading to a complete open circuit or significant calibration drift.

- Diagnosis Tip: If a sensor fails shortly after an unexpected process spike or consistently gives readings that are much lower (for RTDs) or wildly off (for thermocouples) after being exposed to a high-temperature event, overtemperature is highly likely.

5. Contamination & Ageing (Especially for Thermocouples)

Over long periods, especially in high-temperature or chemically aggressive environments, the very materials that make up a thermocouple can change, leading to inaccurate readings, a phenomenon known as “drift.”

- How it Happens:

- Diffusion: At high temperatures, impurities from the process environment or even from the insulating materials within the sensor can diffuse into the thermocouple’s metal wires.

- Oxidation/Reduction: Exposure to oxygen or reducing atmospheres can alter the composition of the thermocouple alloys.

- The Result: These changes alter the thermoelectric properties of the thermocouple, causing it to generate an incorrect voltage for a given temperature, leading to a slow, progressive drift in readings that can be difficult to detect without periodic calibration checks. RTDs are much less susceptible to this.

- Diagnosis Tip: If a sensor gradually starts giving readings that are consistently off compared to a known reference, especially after long service in a harsh environment, contamination or ageing is a strong possibility. This often requires recalibration or replacement.

Conclusion: Don’t Just Blame the Sensor!

The next time a temperature reading goes awry, take a moment before automatically condemning the sensor. By systematically considering these five common failure culprits; mechanical stress, moisture, lead wire damage, overtemperature, and contamination, you can more accurately diagnose the root cause, implement effective corrective actions, and extend the lifespan of your critical temperature measurement infrastructure.