If you’re looking to improve the accuracy and reliability of temperature measurements in your pipelines or vessels then look no further than the helical strake thermowell.

In this article, we touch on the ASME PTC 19.3 standard and explore the benefits of the helical strake design in improving the stability and durability of thermowells.Discover how this design can reduce vortex-induced vibrations by up to 90%, and learn why it’s a reliable option for anyone seeking to increase the reliability of temperature measurements in their industrial processes.

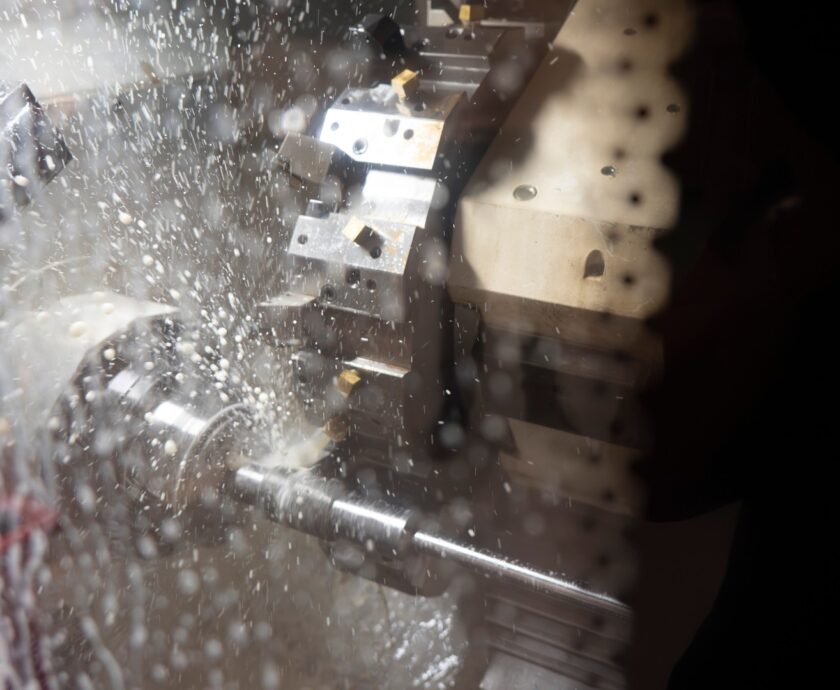

Thermowells are protective devices that hold temperature sensors in a pipeline or vessel. They allow for accurate temperature measurements without exposing the sensor to the harsh environment of the process fluid.

But sometimes, the fluid flow can create shedding vortices, which can cause the thermowell to vibrate and potentially fail. These vibrations are called vortex-induced vibrations (VIV), and they occur when a fluid flows around a cylinder, such as a thermowell, at a certain speed, creating alternating vortices on opposite sides of the cylinder. These vortices can cause the thermowell to vibrate, which can lead to fatigue damage or failure over time.

In order to reduce the amplitude of the vibration, we employ a technique called Damping. This works by modifying the geometry of the thermowell, which is where the helical strake design comes in.

Now, the ASME PTC 19.3 standard sets design standards for thermowells, but it doesn’t cover thermowells with specially designed surface structures like the helical strake. The reason for this is that it’s hard to create design rules that can apply to all these different types of thermowells. The standard can only be used for static calculations, like stress and pressure design, but not for dynamic calculations, like vibration and frequency, which can’t be determined by the formulas described in the standard.

But don’t worry – there are plenty of studies and experiments that have shown the effectiveness of the helical strake design in reducing vibration and potential failure. In fact, some studies have shown that the use of helical strakes can reduce vortex-induced vibrations by up to 90%!

Ready to take the next step in improving your temperature measuring systems? Contact the technical team at Thermo Electric Instrumentation for more information on how the helical strake design can benefit your industrial processes.

With decades of experience in temperature measurement solutions, Thermo Electric Instrumentation is committed to providing high-quality products and exceptional customer service.